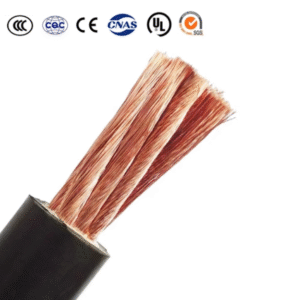

Rubber Cable HO7RN-F

Home > Products > Rubber Cable > Rubber Cable HO7RN-F

Rubber Cable HO7RN-F

HO7RN-F rubber cable – flexible and resistant to abrasion.

Ideal for heavy-duty industrial and outdoor applications.

Waterproof and oil-resistant – built to withstand harsh conditions.

Durable rubber-sheathed cable for mobile and stationary equipment.

Certified HO7RN-F cable – safety and performance guaranteed.

Application

HO7RN-F is a flexible rubber-insulated cable designed for heavy-duty industrial and outdoor applications requiring excellent mechanical strength and environmental resistance. It features fine-stranded copper conductors for superior flexibility and electrical conductivity.

The cable insulation and sheath are made from chlorinated polyethylene (CPE) or synthetic rubber compounds, providing outstanding resistance to oil, acids, alkalis, abrasion, ozone, and extreme weather conditions. This makes HO7RN-F ideal for harsh environments such as factories, construction sites, mining, and agricultural machinery.

Rated for voltages up to 450/750V, HO7RN-F cables support continuous operation at temperatures from -25°C up to +60°C, with short-term overload tolerance up to 90°C. Its high flexibility allows for easy handling and installation in confined spaces or movable equipment.

Compliant with international standards such as HD 22.4 S3, VDE 0250, and IEC 60245, HO7RN-F cables are widely used in portable tools, motor leads, welding machines, and outdoor power distribution.

With robust protection and excellent electrical performance, HO7RN-F rubber cables ensure safe and reliable power transmission in demanding industrial settings.

Specifications

| Category | Technical Description | Typical Applications |

|---|---|---|

| Cable Type | Flexible rubber-insulated and sheathed power cable designed for heavy-duty applications | Ideal for portable tools, industrial machinery, construction sites, and outdoor use |

| Conductor Material | Flexible stranded copper conductors, ensuring excellent conductivity and flexibility | Enables frequent handling, bending, and movement without damage |

| Insulation & Sheath | – Ethylene Propylene Rubber (EPR) or Chloroprene (Neoprene) insulation and sheath providing high mechanical and chemical resistance | Resistant to oils, acids, abrasion, weather, and UV exposure |

| Voltage Rating | Rated for 450/750 V per Harmonized European Standard HD 22.4 S3 and IEC 60245 | Suitable for industrial power distribution and connection |

| Standards Compliance | Complies with Harmonized EN 50525-2-21, VDE 0250, and IEC 60245 standards | Ensures safety, durability, and performance under harsh conditions |

Parameter

Rubber cable HO7RN-F - Reference standard

| Number of cores | Cross-sectional area | Insulation thickness | Overall diameter | Weight |

| mm2 | mm | mm | kg/km | |

| 1 | 1 | 0.8 | 5.7 | 50 |

| 1 | 1.5 | 0.8 | 5.8 | 52 |

| 1 | 2.5 | 0.9 | 6.5 | 67 |

| 1 | 4 | 1 | 7.4 | 92 |

| 1 | 6 | 1 | 8.1 | 119 |

| 1 | 10 | 1.2 | 9.8 | 185 |

| 1 | 16 | 1.2 | 11.35 | 258 |

| 1 | 25 | 1.4 | 13.3 | 375 |

| 1 | 35 | 1.4 | 14.6 | 485 |

| 1 | 50 | 1.6 | 17.2 | 669 |

| 1 | 70 | 1.6 | 19.35 | 892 |

| 1 | 95 | 1.8 | 22.2 | 1160 |

| 1 | 120 | 1.8 | 24.3 | 1436 |

| 1 | 150 | 2 | 25.9 | 1748 |

| 1 | 185 | 2.2 | 29.7 | 2142 |

| 1 | 240 | 2.4 | 31.5 | 2698 |

| 1 | 300 | 2.6 | 36.5 | 3348 |

| 1 | 400 | 2.8 | 40.4 | 4293 |

| 1 | 500 | 3 | 42.6 | 5262 |

| 1 | 630 | 3 | 47.2 | 6790 |

| 2 | 1 | 0.8 | 8.1 | 94 |

| 2 | 1.5 | 0.8 | 9 | 120 |

| 2 | 2.5 | 0.9 | 10.7 | 173 |

| 2 | 4 | 1 | 12.3 | 239 |

| 2 | 6 | 1 | 13.8 | 313 |

| 2 | 10 | 1.2 | 18.6 | 563 |

| 2 | 16 | 1.2 | 21.7 | 830 |

| 2 | 25 | 1.4 | 25.8 | 1211 |

| 3 | 1 | 0.8 | 8.74 | 117 |

| 3 | 1.5 | 0.8 | 8.74 | 147 |

| 3 | 2.5 | 0.9 | 9.68 | 123 |

| 3 | 4 | 1 | 11.48 | 297 |

| 3 | 6 | 1 | 13.2 | 390 |

| 3 | 10 | 1.2 | 14.78 | 705 |

| 3 | 16 | 1.2 | 19.9 | 1031 |

| 3 | 25 | 1.4 | 23.31 | 1512 |

| 3 | 35 | 1.4 | 27.7 | 1907 |

| 3 | 50 | 1.6 | 30.2 | 2651 |

| 3 | 70 | 1.6 | 35.8 | 3484 |

| 3 | 95 | 1.8 | 40.1 | 4594 |

| 4 | 1 | 0.8 | 9.63 | 142 |

| 4 | 1.5 | 0.8 | 46.4 | 180 |

| 4 | 2.5 | 0.9 | 9.63 | 260 |

| 4 | 4 | 1 | 14.6 | 336 |

| 4 | 6 | 1 | 16.4 | 449 |

| 4 | 10 | 1.2 | 21.8 | 833 |

| 4 | 16 | 1.2 | 25.4 | 1138 |

| 4 | 25 | 1.4 | 30.7 | 1714 |

| 4 | 35 | 1.4 | 33.4 | 2204 |

| 4 | 50 | 1.6 | 39.6 | 3029 |

| 4 | 70 | 1.6 | 44.9 | 4121 |

| 4 | 95 | 1.8 | 51.9 | 5361 |

| 4 | 120 | 1.8 | 55.3 | 6546 |

| 4 | 150 | 2 | 60.8 | 8095 |

| 4 | 185 | 2.2 | 65.7 | 9652 |

| 4 | 240 | 2.4 | 75.7 | 12614 |

| 5 | 1.5 | 0.8 | 11.8 | 206 |

| 5 | 2.5 | 0.9 | 14 | 297 |

| 5 | 4 | 1 | 16.2 | 422 |

| 5 | 6 | 1 | 18.2 | 567 |

| 5 | 10 | 1.2 | 24 | 1010 |

| 5 | 16 | 1.2 | 28.2 | 1400 |

| 5 | 25 | 1.4 | 33.9 | 2096 |

| 5 | 35 | 1.4 | 37.2 | 2700 |

| 5 | 50 | 1.6 | 44 | 3730 |

| 5 | 70 | 1.6 | 48 | 5033 |

| 5 | 95 | 1.8 | 53.2 | 6271 |

| 7 | 1.5 | 0.8 | 15.13 | 315 |

| 7 | 2.5 | 0.9 | 17.6 | 445 |

| 12 | 1.5 | 0.8 | 18.2 | 493 |

| 12 | 2.5 | 0.9 | 21.4 | 702 |

| 19 | 1.5 | 0.8 | 22.1 | 710 |

PDF Download

PDF Download

WHY CHOOSE US